The Human-Centric Transformation Of Industry 5.0

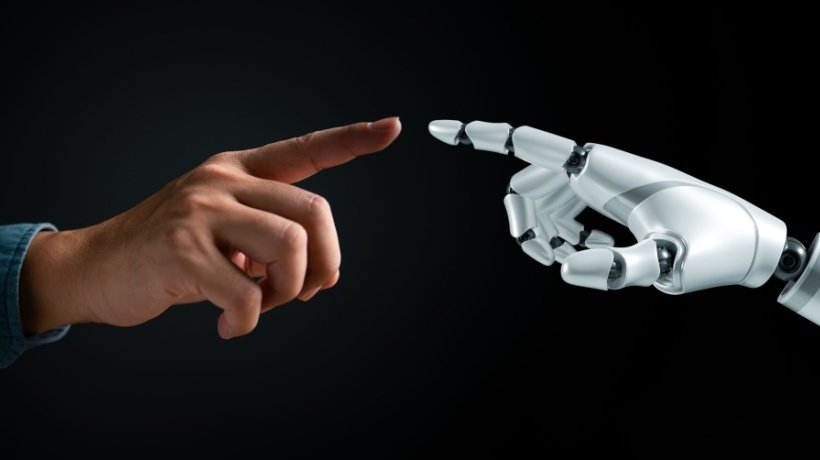

Industry 5.0 represents the next evolution in industrial development, building on the advancements of Industry 4.0, which focused on automation, data exchange, and smart technologies. Industry 5.0 introduces a human-centric approach, emphasizing the integration of human creativity and intelligence with advanced technological capabilities. This new era aims to create a synergistic relationship between humans and machines, enhancing productivity while prioritizing human well-being and sustainability.

Unlike Industry 4.0, which often centered on replacing human labor with automation, Industry 5.0 focuses on collaboration between humans and robots. This collaboration is designed to leverage the strengths of both human ingenuity and robotic precision, fostering an environment where technology augments human capabilities rather than replacing them. The human-centric approach of Industry 5.0 is characterized by personalized manufacturing, sustainable industrial practices, and the adoption of human-centered technologies to create smart factories.

The Role Of Human-Robot Collaboration In Industry 5.0

Central to the concept of Industry 5.0 is the collaboration between humans and robots. This collaboration, known as human-machine collaboration, involves robots and Artificial Intelligence (AI) systems working alongside humans to perform tasks more efficiently and effectively. In this model, robots handle repetitive, dangerous, or highly precise tasks, freeing humans to focus on more creative, strategic, and problem-solving activities. Human-robot collaboration enhances productivity and innovation in several ways:

- Increased efficiency

Robots can operate continuously without fatigue, leading to higher production rates and consistent quality. - Enhanced precision

Robots excel in tasks requiring high precision, reducing errors and waste in manufacturing processes. - Creative synergy

Humans can leverage their creativity and decision-making skills, while robots provide the physical capabilities and data-driven insights. - Flexible production

The collaboration allows for more flexible and adaptable manufacturing processes, accommodating custom orders and rapid changes in demand.

Benefits Of A Human-Centric Future In Industry 5.0

The shift towards a human-centric future in Industry 5.0 brings numerous benefits that extend beyond mere productivity gains. These benefits include improved working conditions, greater innovation, and enhanced sustainability.

Improved Working Conditions

By designing workplaces that prioritize human well-being, Industry 5.0 ensures ergonomic and safe working environments. This focus on human-centric manufacturing reduces workplace injuries and enhances job satisfaction.

Greater Innovation

With robots handling mundane tasks, humans can focus on creative and innovative endeavors. This leads to the development of new products, services, and solutions that drive business growth.

Enhanced Productivity

Human-machine collaboration boosts productivity by combining human creativity with robotic efficiency. This synergy results in faster production cycles and higher-quality outputs.

Personalized Manufacturing

Industry 5.0 technologies enable the customization of products to meet individual customer preferences. This personalized manufacturing approach enhances customer satisfaction and loyalty.

Sustainability

The human-centric approach promotes sustainable industrial practices by minimizing waste, reducing energy consumption, and encouraging the use of environmentally friendly materials and processes.

How Industry 5.0 Is Transforming Manufacturing

Industry 5.0 is transforming manufacturing by integrating advanced technologies and fostering a human-centric approach. This transformation is characterized by the adoption of smart factories, the use of Industry 5.0 technologies, and the implementation of next-gen industrial revolution strategies.

- Smart factories

Smart factories leverage the Internet of Things (IoT), AI, and advanced robotics to create highly automated and connected production environments. These factories are capable of real-time data analysis, predictive maintenance, and adaptive manufacturing processes. - Industry 5.0 technologies

Key technologies driving Industry 5.0 include AI, robotics, IoT, and advanced data analytics. These technologies enable manufacturers to optimize production, improve quality, and reduce costs. - Next-gen industrial revolution

Industry 5.0 represents the next-gen industrial revolution, where the focus shifts from mass production to personalized, sustainable, and human-centric manufacturing.

Industry 5.0 trends indicate a growing emphasis on flexibility, adaptability, and customer-centric production models. This transformation is making manufacturing more responsive to market demands and capable of delivering customized solutions.

Sustainable Practices In The Era Of Industry 5.0

Sustainability is a core principle of Industry 5.0. The emphasis on sustainable industrial practices aims to minimize environmental impact and promote the responsible use of resources. Key sustainable practices in Industry 5.0 include:

Resource Efficiency

Industry 5.0 technologies enable manufacturers to optimize resource use, reducing waste and improving energy efficiency. This includes the use of renewable energy sources and recycling materials.

Green Manufacturing

Sustainable industrial practices involve adopting environmentally friendly production methods, such as using biodegradable materials and reducing emissions.

Circular Economy

Industry 5.0 supports the circular economy model, where products are designed for longevity, reuse, and recycling. This approach minimizes waste and promotes the sustainable use of resources.

Environmental Monitoring

Advanced data analytics and IoT technologies allow for real-time monitoring of environmental impacts, enabling manufacturers to quickly identify and address sustainability issues.

Conclusion

Industry 5.0 represents a paradigm shift in industrial transformation, where the focus is on creating a human-centric future that leverages the strengths of both humans and machines. This next-gen industrial revolution emphasizes collaboration between humans and robots, personalized manufacturing, and sustainable industrial practices. By prioritizing human well-being and sustainability, Industry 5.0 aims to create a more innovative, productive, and environmentally responsible industrial landscape.

The benefits of a human-centric future in Industry 5.0 are manifold, including improved working conditions, greater innovation, enhanced productivity, and sustainable practices. As Industry 5.0 continues to evolve, it will redefine the future of manufacturing, creating smart factories that are adaptive, efficient, and capable of meeting the diverse needs of customers in a sustainable manner. Through the adoption of human-centered technology and advanced Industry 5.0 technologies, the manufacturing sector is poised to achieve a harmonious balance between technological advancement and human creativity, paving the way for a prosperous and sustainable industrial future.